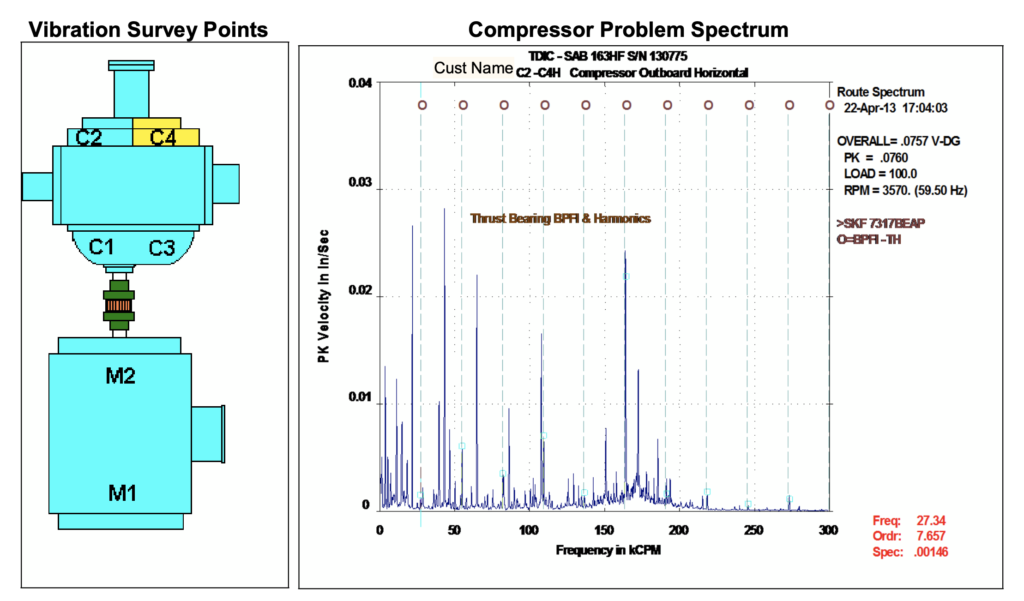

Vibration Analysis

Want to know the vitals on your equipment?

Save time and money with preventative vibration analysis. Vibration analysis will provide you with information on the health and condition of your machinery, and allow you to take prompt corrective action. This results in optimized machine productivity, extended machine life, and reduced maintenance costs.

A glitch in a bearing, screw surface or slide can result in a failure of the compressor. Failures in ammonia compressors often correlate with the loss of some amount of the ammonia refrigerant, resulting in the creation of occupational hazard and possible fines if not reported correctly.

View Sample Report: Sample Vibration Analysis Report

Call us today to schedule your vibration analysis at 1-866-383-2653.

Piping and Instrumentation Diagram/Drawing (P&ID)

Piping and Instrumentation Diagram play a significant role in the maintenance and modification of the process that it describes. It is critical to demonstrate the physical sequence of equipment and systems, as well as how these systems connect. During the design stage, the diagram also provides the basis for the development of system control schemes allowing for further safety and operational investigation.

For processing facilities, it is a pictorial representation of:

- Key piping and instrument details

- Control and shutdown schemes

- Safety and regulatory requirements

- Basic start up and operational information

List of P&ID items:

- Instrumentation and designations

- Mechanical equipment with names and numbers

- All valves and their identifications

- Process piping, sizes, and identification

- Miscellanea – vents, drains, special fittings, sampling lines, reducers, increasers, and swagers

- Permanent start-up and flush lines

- Flow directions

- Interconnections references

- Controls inputs and outputs, interlocks

- Interfaces for class changes

- Computer control system input

- Identification of components and subsystems delivered by others